Losing power

24 Answers

Sammy1z123 answered 7 years ago

It could be as simple as a bad fuel filter or as complicated as a bad fuel pump. By the looks of that truck, that is a pretty new truck. Or did you by any chance put some bad gas in your truck? If you did, ask a local dealer what is the best gas additive. Hey, just don't throw additives in your gas tank, it might damage your fuel system.

I put the best one which is 91 here in California but thank you

Coil pack fir,e the plug,s

I think on your model it has coil for each plug,one of them may be going bad,the way you talk it only doe,s this between certain speed,s.

If it doe,s not have but one coil pack on it,and has a distributor,it may be the coil module in the distributor.

When it doe,s it do you have a engine light on?

I had the check engine light on but then it turns off and then comes back on

That is good if it is in and out,go to a parts store and have it scanned,the computer hold,s the code and they can tell you why the truck is doing this,but IMO it will be one of the coil pack,s.

I've had it scanned before and it gives a p3400 code

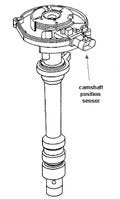

Thank you this may help you,this is the cam shaft sensor all so called the distributor module,it is in the distributor and it will cause what your truck is doing,

In old cars it is called a pick up module,it controls how much fire and fuel the truck need,s a certatin rates judge by the ECM,

I can't seem to even find the distributor in the truck

Should be at the fire wall in very back of engine,hard to see.

There is no distributor on this engine. The p3400 code is telling the story... P3400 CHEVROLET - Cylinder Deactivation System Performance...Possible causes: Faulty Cylinder Deactivation Solenoid, Cylinder Deactivation Solenoid harness is open or shorted, Cylinder Deactivation Solenoid circuit poor electrical connection...The control module detects that the actual measured values from the MAF sensor, MAP sensor, and TP sensor, is not within the range of the calculated values for cylinder deactivation mode Possible symptoms Engine Light ON (or Service Engine Soon Warning Light) P3400 CHEVROLET Description To provide maximum fuel economy under light load driving conditions, the Engine Control Module (ECM) will command the cylinder deactivation system ON to deactivate engine cylinders 1 and 7 on the left bank, and cylinders 4 and 6 on the right bank, switching to a V4 mode. The engine will operate on 8 cylinders, or V8 mode, during engine starting, engine idling, and medium to heavy throttle applications. When commanded ON, the ECM will determine what cylinder is firing, and begin deactivation on the next closest deactivated cylinder in firing order sequence. The Gen IV engine has a firing order of 1-8-7-2-6-5-4-3. If cylinder number 1 is on its combustion event when cylinder deactivation is commanded ON, the next cylinder in the firing order sequence that can be deactivated is cylinder number 7. If cylinder number 5 is on its combustion event when cylinder deactivation is commanded ON, then the next cylinder in the firing order sequence that can be deactivated is cylinder number 4. Cylinder deactivation is accomplished by not allowing the intake and exhaust valves to open on the selected cylinders by using special valve lifters. The deactivation lifters contain spring loaded locking pins that connect the internal pin housing of the lifter to the outer housing. The pin housing contains the lifter plunger and pushrod seat which interfaces with the pushrod. The outer housing contacts the camshaft lobe through a roller. During V8 mode, the locking pins are pushed outward by spring force, locking the pin housing and outer housing together causing the lifter to function as a normal lifter. When V4 mode is commanded ON, the locking pins are pushed inward with engine oil pressure directed from the valve lifter oil manifold (VLOM) assembly solenoids. When the lifter pin housing is unlocked from the outer housing, the internal pin housing will remain stationary, while the outer housing will move with the profile of the camshaft lobe, which results in the valve remaining closed. One VLOM solenoid controls both the intake and exhaust valves for each deactivating cylinder. There are 2 distinct oil passages going to each cylinder deactivation lifter bore, one for the hydraulic lash-adjusting feature of the lifter, and one for controlling the locking pins used for cylinder deactivation. Although both intake and exhaust valve lifters are controlled by the same solenoid in the VLOM, the intake and exhaust valves do not become deactivated at the same time. Cylinder deactivation is timed so that the cylinder is on an intake event. During an intake event, the intake cam lobe is pushing the valve lifter upwards to open the intake valve against the force of the valve spring. The force exerted by the valve spring is acting on the side of the lifter locking pins, preventing them from moving until the intake valve has closed. When the intake valve lifter reaches the base circle of the camshaft lobe, the valve spring force is reduced, allowing the locking pins to move, deactivating the intake valve. However, when cylinder deactivation is commanded ON, the exhaust valve for the deactivated cylinder is in the closed position, allowing the locking pins on the valve lifter to move immediately, and deactivate the exhaust valve. By deactivating the exhaust valve first, this allows the capture of a burnt air/fuel charge or exhaust gas charge in the combustion chamber. The capture of exhaust gases in the combustion chamber will contribute to a reduction in oil consumption, noise and vibration levels, and exhaust emissions when operating in V4 mode. During the transition from V8 to V4 mode, the fuel injectors will be turned OFF on the deactivated cylinders. The ignition system secondary voltage or spark is still present across the spark plug electrodes on the deactivated cylinders. If all enabling conditions are met and maintained for cylinder deactivation operation, the ECM calibrations will limit cylinder deactivation to a cycle time of 10 minutes in V4 mode, and then return to V8 mode for 1 minute. Switching between V8 and V4 mode is accomplished in less than 250 milliseconds, making the transitions seamless and transparent to the vehicle operator. The 250 milliseconds includes the time for the ECM to sequence the transitions, the response time for the VLOM solenoids to energize, and the time for the valve lifters to deactivate, all within 2 revolutions of the engine crankshaft.