2006 Toyota Corolla S , just changed my friction disc and pressure plate and release bearing , my clutch pedal and cylinders are working fine on my fork/release bearing , But I can't shift into gear! Its not allowing the "break?" Or "pause?" To go between gears or into a gear ? What did I do wrong? Was shifting fine before I did the work but pressure plate was effed and tranny wasn't "catching" when accelerating

Asked by Toyotapizzaninja Jun 27, 2015 at 02:36 PM about the 2006 Toyota Corolla S

Question type: Maintenance & Repair

Manual transmission heeeellllp

30 Answers

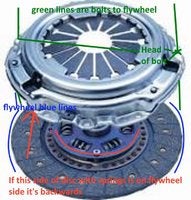

Did you put the disc in backwards, wrong side to flywheel? I will try to find more info

Toyotapizzaninja answered 9 years ago

Haven't opened it back up yet to look at that, when bolting back on the pressure plate is it possible to go too tight and have it seize the friction disc in place? Idk eff all about transmissions :-/ couldn't afford to pay someone to replace it tho :-/ Yaaaay hand tools :-/

Toyotapizzaninja answered 9 years ago

Yes used tool to align ,that bearing was for my fork"throw out bearing"

No. The bolts that go through pressure plate on to flywheel have to be tight, I don't know the spec but no. that would not bind it. I know my two pictures look different, but they are both from Corolla parts images. I hate to have you take it apart just because I had that thought and am wrong, but the disc can only work one way

Yes, that is what pushes on leaves on pressure plate to release disc from flywheel. Then when released those same leaf springs hold the disc to flywheel and friction takes over to spin shaft

Just to be sure I understand, you push the pedal and clutch does not disengage. You can be pushing on pedal, and in gear, hit starter it would lurch. Running, it grinds trying to put in gear. .....Right?

Toyotapizzaninja answered 9 years ago

Right, it's all working (cylinders,clutch pedal) can start but when trying to put into gear its like a hard shift that doesn't allow my gearshifter that smooth transition, maybe put friction disc backwards?

Toyotapizzaninja answered 9 years ago

Does the real release bearing need to go between the leafs and friction disc ? Or does that stay on the fork and just travel over the shaft towards the pressure plate?

It stays on fork and pushes on leaves, "throwout bearing" does NOT go in between leaves. I hope you can see this, I keep getting Thank you your answer will be posted shortly,

Toyotapizzaninja answered 9 years ago

Ok so if I installed the friction plate backwards then it wouldn't allow me to shift "cleanly/smoothly" without that "hard shifting/grinding into" gears?

That's correct. It would not release. But just a thought, have you checked the fluid? It shares reservoir with brake master cylinder. And again, i really hate to be wrong that you did put it in backwards, tear it apart only to discover you had it right. i would feel terrible

But if everything else is right, the master cylinder, slave cylinder, all is right that's all I can think of, assuming you have the right clutch assemply

They took down my drawing from a PUBLIC DOMAIN that I manipulated

Toyotapizzaninja answered 9 years ago

Lol I hear ha , 18hrs to take apart and put back together in my driveway with hand tools lol :-/ , but yes , push in clutch and it pumps fluid through to that cylinder on the front of the engine that pushes against the fork with the bearing on it , so that part works , just no play on my shifter because I'm assuming the tranny is still connected and turning . P.s those drawings helped!

Toyotapizzaninja answered 9 years ago

Yes the clutch assembly looked identical to the one I pulled out , after bolting the pressure plate to the engine (on top of the friction plate) should the friction plate be able to turn somewhat freely behind the pressure plate?

No. Disc, or (friction plate, same thing) should be firm and tight. No movement at all....clutch is 'engaged'. Then when throwout bearing pushes on leaf springs on pressure plate, disc then disengages, allowing you to shift and get in to gear

Sorry, I didn't leave you i went to get lunch. The springs in the disk are to soften the application of the friction. They allow it to move, just a little bit, the torque between the splines and friction material. So that way it's not a sudden hard torque and saves disc from breaking apart between splines and 'grabbing' surface

From above, what you wrote....I don't want this to turn out to be simply out of adjustment. But if you say...and you're the one will know.... the throwout bearing is pushing on leaves, then right back to where we started. That was my first thought because I have done it. Not on my Corolla (I have a 2006 also) it was a Pontiac. many many moon ago

http://auto.howstuffworks.com/clutch1.htm check it out. on the side view click the box disengage clutch. It kinda cool, interactive

Toyotapizzaninja answered 9 years ago

Sweet, I fell asleep in front of my new fan lol....yea I'm assuming it's just a backwards disc then (hoping) I'll know by the end of the day Sunday when I rip into it again , cuz it should be working from the sounds of everything and what you told me, that's the only thing I can think of that could have gone wrong with my re instal

Toyotapizzaninja answered 9 years ago

Does the release bearing need to push on those springs really hard or just make contact and slightly push against the friction disc?

Really hard. It takes a lot of pressure to hold disc on flywheel, the entire torque of engine passes through it. If soft it's not releasing clutch

Toyotapizzaninja answered 9 years ago

Yes that was the issue, disc was installed backwards :( new issue though after 3 hours of trying I can't get me tranny back mounted to the engine :( using jacks and muscle :-/ been a bit ch

You use the plastic dummy shaft to center the disc..right? It goes through splines in to pilot hole/bearing to center it

Toyotapizzaninja answered 9 years ago

Yea , centred , removed tool after re bolting the pressure plate, it's just reaching ion through the top of the hood to constantly lift it onto my hydraulic jack, it didn't help being a tar deadly hot day, need a engine hoist :-/ gonna try again early morning when it's cool outside