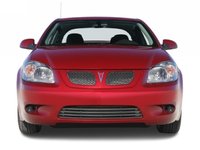

2009 Pontiac G5 2.2 Ecotec.

Asked by Countryboyauto Jan 12, 2021 at 06:12 PM about the 2009 Pontiac G5 Base

Question type: Maintenance & Repair

Just stopped running, cyl 1 30 psi compression, from there the compression went to 20,10 & 10. Timng chain looks tight and dead on, head gasket looks ok, valves arent bent. Why no compression then please help

13 Answers

Low compression means it will not run. I don't know if you had a head gasket failure or something worse. You will need a mechanic to evaluate it.

Goodwrench707 answered 3 years ago

30 psi is cool , but 10, 20 on others, you have a problem.. The timing chain might look OK to you? If it jumped a couple teeth, will still look OK. You might have a bad tensioner, that let it jump a tooth or 2. Only way to find out, is to open it up. Sorry for bad news. But this is an interference engine. If the timing chain has problems, the valves are bent. The piston will come up and bend them. I wish I had better news for you. But I do not.

Goodwrench707 answered 3 years ago

I have a smile on my face, in profile pic, but not to make fun of your situation. It's just there to show I'm a friendly mechanic.

Low compression test readings like that on all cylinders means it's jumped timing. Reset the valve timing and replace the timing chain, sprockets, and tensioner if equipped. Hopefully this is not an interference engine. If it is an interference engine the valves are bent too. Hope that helps! Jim

150 psi is good. 30 psi might as well be zero.

Countryboyauto answered 3 years ago

Ok guys thanks, when I pulled the covers off and set the engine tdc all the timmimg marks on engine and chain are lined up perfectly. Wet compression test changed nothing , pulled head . Head gasket looks good no blow out marks and the valves are all closed tightly. My question is this, on this particular engine if the hydraulic tensioner is bad causing slack during cranking would that slack be enough to cause this ? I didn’t check for “cranking” slack before I pulled it apart but the main tensioner is weak

For every two revolutions of the crankshaft sprocket the camshaft sprocket turns one complete revolution. Make sure you're at top dead center on the correct cylinder. Not all engines use number one to set the valve timing. Most do, but not all. Some engines also need to have the crankshaft and camshaft dimples both at 12 o'clock. Others need the crankshaft dimple at 12 o'clock but the camshaft dimple at 6 o'clock. You could now be 180° out. Are all the valves tightly closed with the head off? They should be. If not, the valves are bent. Hope that helps! Jim

Just reread your post and see the valves are tightly closed. So that's good. The lack of compression on all cylinders is definitely a valve timing problem then! Jim

Upon doing further research I see you have VVT (Variable Valve Timing) on this engine. While I'm not familiar with these systems I can tell you that something went haywire with it and your valve timing is off enough to cause the engine to stop running due to lack of compression. I would get the Delco kit, which appears to have everything needed to repair the VVT system and get the valve timing set correctly so you'll be back on the road again. Hope that helps! Jim

Countryboyauto answered 3 years ago

If I remove the cams the valves are all closed tightly but with the cams in some are not closed all the way . On an ecotec vvt head is this normal or should ALL valves be closed tightly with cams in ?

That's normal. Some cylinders are on the intake stroke, some are on the exhaust stroke so some valves will be open or partially open. Cylinders that are on the compression stroke will have closed valves. This is where valve timing comes into play. On cylinders that are on the compression stroke the valves need to be closed so when the piston comes up inside the cylinder the air/fuel mixture is compressed to about 150 PSI or so. Then the spark plug fires to create the explosion of the compressed air/fuel mixture and the piston is forced down, by the explosion. This is the power stroke of the cylinder that makes the engine run. The valves must be timed correctly in sync with the piston to make all of this happen. As the camshaft spins the lobes on the camshaft open the valves and allow them to close. The pistons are attached to the crankshaft. As the pistons go up and down in the cylinders the crankshaft spins. The camshaft and crankshaft are linked together by the timing chain. The camshaft and crankshaft have to be in the proper positions in relation to each other so the engine will run. Hope that helps! Jim