what position is the ignition rotor underneath the distributor cap in a 97 c1500 5.7L?

Asked by woodywood55 Aug 14, 2008 at 01:29 PM about the 1997 Chevrolet C/K 1500

Question type: Maintenance & Repair

29 Answers

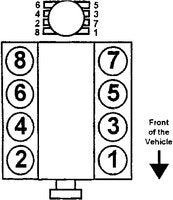

You really need a scan tool to set timing properly. Try crank the motor to TDC on the compression stroke on cylinder 1, pull the distributo rcap off and line up the rotor with the number 8 in the distributor base - you'll need a good light.

What do you mean what position should it be in? If you mean how do i get it in time its this simple. Bring your number one cylinder to top dead center. You can tell its top dead by taking out the spark plug and feeling the piston with a screw driver. After this, drop the distributor into place with the rotor pointing towards number 1 cylinder. On a vortec 350 the computer allows you a "window" you have to be in to have the engine in time, this is allowed because the spark is comptuer controlled, therefore no timing light is needed. It will automatically adjust to perfect time. So basically if you get it to top dead and pointed to number one, you should be fine.

wow wow wow what are U talkin about, oh yeah and Mike theres a 50 50 chance U will get it 180 off with your method(the screw driver ...bumping the starter over until U hear compression exscaping the spark plug hole guarantees U are on #1 compression stroke.

if you put #1 at tdc on compression and line it up to #8 the timing would be retarded as hell and you would have precombustion this is straight out of chiltons online 1. Start the engine and allow it to reach operating temperature. Stop the engine and connect the timing light to the No. 1 (left front) spark plug wire, at the plug or at the distributor cap. Do not pierce the plug wire insulation with HEI; it will cause a miss. The best method is an inductive pickup timing light. 2. Clean off the timing marks and mark the pulley or damper notch and timing scale with white chalk. 3. Disconnect and plug the vacuum line at the distributor on models with a carburetor. This is done to prevent any distributor vacuum advance. On fuel injected models, disengage the timing connector which comes out of the harness conduit next to the distributor, this will put the system in the bypass mode. Check the under hood emission sticker for any other hoses or wires which may need to be disconnected. 4. Start the engine and adjust the idle speed to that specified on the Underhood Emissions label. With automatic transmission, set the specified idle speed in Park. It will be too high, since it is normally (in most cases) adjusted in Drive. You can disconnect the idle solenoid, if any, to get the speed down. Otherwise, adjust the idle speed screw. The tachometer connects to the TACH terminal on the distributor and to a ground on models with a carburetor. On models with fuel injection, the tachometer connects to the TACH terminal on the ignition coil. Some tachometers must connect to the TACH terminal and to the positive battery terminal. Some tachometers won't work with HEI. WARNING Never ground the HEI TACH terminal; serious system damage will result. 5. Aim the timing light at the pointer marks. Be careful not to touch the fan, because it may appear to be standing still. If the pulley or damper notch isn't aligned with the proper timing mark (see the Underhood Emissions label), the timing will have to be adjusted. TDC or Top Dead Center corresponds to 0°B, or BTDC, or Before Top Dead Center may be shown as BEFORE. A, or ATDC, or After Top Dead Center may be shown as AFTER. 6. Loosen the distributor base clamp locknut. You can buy trick wrenches which make this task a lot easier. 7. Turn the distributor slowly to adjust the timing, holding it by the body and not the cap. Turn the distributor in the direction of rotor rotation to retard, and against the direction of rotation to advance. 8. Tighten the locknut. Check the timing again, in case the distributor moved slightly as you tightened it. 9. Reinstall the distributor vacuum line or the timing connector. Correct the idle speed. 10. Stop the engine and disconnect the timing light.

and no a scan tool does NOT help with timing on a car with a distributor

my 5.7 is missing all sorts of stuff to do the timing. i need to find a '97 5.7 vacuum advance distributor, i also need the crankshaft pointer and scaled harmonic balancer, is there any chance i can take those off my '83 350, no wait that doesn't have vac adv either. maybe there is some sort of plug and play device that would read the ecm and show differences in the crank and cam sensor positions...any help? i'm hoping to get it within 2 degrees of dead on.

im working on a 5.7 chevy now if i time the engine with the number 1 cylinder up on compression and timing mark on pully lined up for top dead center and the rotor is on number one it will not start but if i turn the dist to where it is on number 8 then it will start but runs ruff and misfires can any one give me some advise

Actually a timing gun is near useless for this vintage. The best you can do is top dead center line up all the marks on the distributor and reinstall it. The computer should be able to time it fairly closely untill you can have a shop time it with a scanner. I know you old fogies think this is stupid and im with you, but as i found out you cannot time it with a timing gun because the computer will fight you with any adjustments. I mean besides the fact that theres LITERALLY NOTHING to point the timing gun at

Sundevildaddy answered 8 years ago

1990 k1500 5.7l TBI here: Run engine to OP.Temp. Disconnect TSL (timing service line) brown w/ black stripe (mine is located at firewall, some models [same year] are under glovebox insert at ECM). (If timing is off to start with:) Timing light, adjust dist. to 0°. Engine off, disconnect battery. Grab a helper, pull #1 plug, place finger over plug hole, manually rotate crank until you feel pressure (not suction). Check piston position with screwdriver (gently - don't want to mar piston), you want piston at apex of that stroke. This is tdc. You're timing mark should show aligned. Follow manufacturer instructions to install/replace distributor. Reconnect battery Reconnect TSL Start motor. *note: if you're like me, you like a little extra "oomph" on the throttle - I advance mine up to 20° when setting timing. The ECU reads whatever position you set it as 0° and adjusts based on load and/ or kncok & emmissions reading (GM shop bulletin - sorry, no reference to give atm, but I have read it myself). To advance set timing, reconnect battery (do NOT reconnect TSL). Start motor, advance by light/ear, shut off, disco' battery for 2 minutes (or bump ignition to discharge system). Reconnect battery, reconnect TSL, start motor and allow to idle ~2 mins.

Just so it is straight here, John has no idea what he is talking about. Read all the cheap manuals you want, just better make sure they are for the right year. All Vortec motors need a scan tool or something like EFI Live to access CMP Retard Offset PID. You will forever have a P1345 code otherwise and a vehicle that doesn't run like it should. From his copied instructions it is clear he has no idea what he is quoting. There is no "timing connector" or "vacuum" lines. It is possible to get lucky with these, but less than likely. Any decent shop with an old "brick" scanner should be able to get you setup for no more than 1 hour of shop time, or even free as it is pretty simple if you didn't get one tooth off dropping the dizzy in the first place.

I don't have an answer, yet a question. I bought a 96 suburban 7.4 and was told the distributor timing needed to be set. So I set it To, pulled the distributor out lined everything up and installed. I had my gorgeous woman maintain above 1000 rpm and tried setting the retard. Closest I get s .8!!! WTF after I get that close it gets worse again. So my question is, is there a vacuum and/or an electrical connector that needs to be unplugged prior to the produre? And yes im watching with live data. Your help s greatly appreciated

Not an answer but I have a 97 Chevy k 1500 with 5.7 and I replaced the distributor and after I did so it would not start what is the best way to get it in time with out a timing light or just get it close so I can get it to someone who does

I dunno, Iv'e been a mechanic since 1966 and John, pretty much has it nailed.

There's only one person in here that knows what he's talking about by

Vortec 350 is computer timed. No timing lights and such. Got to get it to TDC on compression stroke and then stab distributor with rotor ending up pointing to #1 on the cap.

1 timing these cmputer controlled trucks ect._. You un plug the brown wire to put it into limp mode then you can use a timing light

Your all wrong including seasoned professionals ..same like distibutors do not require TDC But they require Housing and manifold Marks to identify positioning for reinstall. If you screw it up .. then you have to reinstall .. making the marks for the oil pump are easy but newer gm's do not have the old school method of TDC install's... they require scan tool for retadard

Try timing off #6 then yea for sure need scan to fine toon

Wow, one guy had and now two. The rest are clueless or need to pull head out of there ass. Either people dont read original post or they are just ignorant. Im not wasting any more tome here so listen to john or guru and you'll get there. GOOD LUCK

Dave_Wikle answered 5 years ago

Final answer: 96 to 98 vortec 5.7 not like old chevy V8's. Spark timing 100% computer controlled. The cam sensor in the distributor controls CMP = Cam Retard Offset which is the injector timing, not spark. TDC happens twice on a 4 stroke. You want TDC when on power stroke. Remove #1 plug, insert rubber hose, other end to mouth, tongue test…turn crank- when the bigger air comes out at TDC after the compression stroke you have the power stroke not the intake stroke. Groove in balancer meets grove in timing cover=TDC. Then look at where tab of rotor is. It should be at the little triangle with 8 on it (cylinder 1 on cap) If these 2 things are good you should be too. If not, no marks on distributor or block will help you- start from scratch. Set crank to TDC power stroke as above. Remove rotor button to see rotor below; remove distributor hold-down; mark position on distributor before pulling out so you can see how much the cam gear turns it backward as you pull it out. You need to set the rotor so it ENDS UP at the little triangle w/ 8 on it (#1 cyl) when fully seated, so starting position will be upstream (counterclockwise) from there by the amount you marked & noted. The tricky part when doing this is lining up the oil pump key and slot so it too will go in when fully seated. Long screwdriver, flashlight, etc. Set rotor tab to upstream, drop into position. If it doesn't go all the way the first time (never seen this) but up 1/4" the oil key not lined up- hand tighten the hold down & bolt so it doesn't pop out, and bump the starter (turn ignition key on a split second) (have that coil wire safely elsewhere…) and then jiggle the distributer (and repeat if necessary) until it goes in all the way. You can use a 16mm wrench on the crank bolt to do the same thing. The benchmark is TDC power stroke and rotor tab facing the little triangle on the distr body, not the bigger one with 6 (unless you have a 6 cyl vortec....) If your cam is OK and your timing chain isn't stretched, you may not even have to set the cam offset with a scanner. Cheap scanners don't have the CMP monitor (google "how to set cam retard offset CMP")

donsmobile answered 5 years ago

if these gentlemen would look at the year of the vehicle and see that it is a 97 they may know that they are mistaken and that they will need a scan tool

Dave_Wikle answered 5 years ago

donsmobile- you're right if it doesn't seat to the 0 degrees +/- 2 degrees and expect perfection, but if you have the right tooth in the distributor cam gear, the engine turned to TDC power stroke, the rotor button tab is pointing to the small triangle w/ 8 (i.e., the #1 cyl plug wire contact in the distr. cap) and (I didn't mention before, and this helps) the orientation of the flat side of the distributor almost parallel with the intake manifold (closer at the pass side, a tad wider at the driver side but not much) and your chain is good, etc. then you will be so close that the slop in the distributor you would be adjusting during the cam retard process would be small. Certainly won't be throwing codes. I have a 97 k1500 z71 with 5.7 vortec and passed CA smog even with +12 degrees (no codes) before I figured out all the intricacies of getting everything aligned right as above. Too much baloney on the web and youtube, and lots of people telling you to align your V8 vortec to the big triangle with the 6 with the stamped 8 on the rotor (not the button) etc. That's why I posted. And so you are mostly right but it is not an absolute. Me, I do the above and yes I do go to the scan tool (at some point...) to get to the 0 degrees (which few understand the meaning of because they are into the mentality of the old school small block chevy 350 where spark timing is set by turning the distributor similar to the way cam retard offset is adjusted on these vortecs and they get confused. Again, the spark timing is set by the computer, and the PCM won't let you out of the garage if it is going to foul your engine; the cam retard finely tunes the fuel injector timing for that last little bit of creamy goodness (performance, power, mileage....) So since you mentioned it, in the (more expensive) scan tool you find CMP data, get engine to 1100-1500rpm (and for a one-time reading you can zoom it up there once & read without being under the hood) and if adjusting in real time, crawl under hood, loosen distributor hold-down, and if CMP is too positive, you turn distributor clockwise; if too negative counterclockwise, all this with engine at 1100rpm and so somebody is watching the scan tool degrees and yelling at the other guy turning distributor body and then tightening the hold down bolt again. Yes, it is a pain.

No answer but question and sounds like good sound advise have done all these about 7 or 8 times total I’ve lost count at this point. So I’ve got a 97 gmc k1500 with the 5.7 vortec. Truck always fired right up when I first cranked it especially if it was a little chilly out. After a couple cranks or if it sat in the sun for a while it wouldn’t start up as easy and had to hold the key longer to get it started. Then I noticed a little stubble going from idle to operating speed, so knowing that gm caps on these trucks attract moisture and are notorious for corroding, I replaced the cap and rotor button with a black accel cap and rotor with brass terminals, no more stubble. Still issue with starting after sitting a while, still fired right up on first start of the day. So then one day I was pulling a fairly heavy enclosed trailer made about an hour and 45 minute trip, came back unloaded trailer, then proceeded to drive trailer to work, truck cranked up fine that morning got to work, pulled around back. Got back in truck to crank up on break to go wash trailer and nothing, that’s how all my trouble started. But while I was pulling the trailer up a slight hill before it died it jumped or jerked a little but I didn’t think anything of it because my trans is missing overdrive and the other gears aren’t the greatest. So at first I though a coil then ignition control module, replaced both still nothing, took off, took back. Checked fuel pump relays and fuses, checked fuel pressure, getting 60 psi to rail, pump good. I know it takes at least 55 psi to fire injectors on the spider vein systems, fairly certain it’s getting fuel cause plugs are wet and pump is whining and pump is working, have taken number one plug out and put finger over hole with someone turning over till it blew my finger out, lossened clamp took out distributor put back in lined up with timing marks on balancer and cover and had rotor pointing at 1, done this like I said at least 7 or 8 times, so needles to say I’m at my whits end with this thing. Truck would actually crank up run and die at 180 out and not when its at tdc. So I don’t know if the chain has a ton of slack and skipped a tooth on the timing gear, of if I have one or more lobes flattened on the cam. Btw, when I had the distributor out the gear on the bottom was perfect.

Dave_Wikle answered 5 years ago

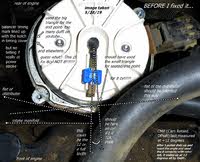

I'd start with the easy things first. I bought my 97 k1500 (5.7) used for a song a few hundred thousand miles ago; I feel your pain. Just going on the "plugs are wet" and "engine is dying" and the fact that you pulled the distributor out suggests a CMP issue. You may just be off a tooth in the distributor. I uploaded an image of my rotor/distr before I "fixed" it... with notes; it shows what I was talking about previously. It was +12 degrees then without scan tool, it ended up at +2 (and I can probably jiggle to zero from here.) I measured it post surgery, not while turning distributor, just to prove that the engine and distributor were actually designed to fit and run without having to use a scan tool (but you'll never know without one!) Timing chain could be stretched, and this can be done in your driveway for less than $100 but there is a learning curve and online videos have a lot of misinformation. Mostly about the rtv sealer placement. By the way, I became a MASTER harmonic balancer puller / water pump installer in the process, a dubious honor. The easiest thing could be air filter and MAF if fuel pressure and spider injection is good. $12 can of MAF cleaner (no substitutes! Use the whole can, let it dry out before reassembly- you're not doing this twice, you're buying a new maf if the spray "fixes" it) would tell you, but a temporary measure only. But in light of the original thread, you should take a scan reading of the cam retard (CMP) value (not on cheaper scan tools under $400) and make sure you are dialed in to zero degrees (spec says +/- 2 degrees but you want it at zero.) My thought is if it is dying on you there's a lack of fuel or air somewhere (big help, huh.) If your CMP is dialed in, you probably don't have a distributor issue, but they do wear out and if a wire to the cam sensor (or any other) got fried on the manifold somewhere, it could short stuff in the ecu. Look for blown fuses (but check engine light should be on...)

Andross2021 answered 4 years ago

Hopefully you didnt do what i did, i just replaced the heads on my 99' 5.7 ltr 350 vortec yukon, i turned the engine to where the #1 was up, but not knowing it before i set the heads and torqued everything down that i preset my cam etc. To be 180 degrees out, i did not have the distributor in, nor did i know about the crank balancer and tdc timing mark on the timing chain cover. Now i have to pull the distributor, set the balancer and timing marks then restab the distributor.

Why are their so many (mechanics) on here that have no clue on setting the timing on a 1997-1998 Chevy 5.7 VORTEC?????? You definitely need a scan tool, not a cheap obd2 reader..... this is kind of embarrassing, this is why so many people don’t trust mechanics, that should be about an hour job to set timing, but so many of you have no clue this is where people gets charged 3-4 times what it should cost.... SHAME ON YOU ALL THAT DO THIS

Guru99M5RZ answered 4 years ago

I set it by using an obd 2 scanner! I kept re seting the code, putting it to tdc, adjusting the distributor, then starting it and repeates the process till I got it to stop throwing the cam and crank coralation code.... pain but I eventually got it

Guru99M5RZ answered 4 years ago

Real micanics find a way because they completely understand how things work

There's absolutely a way to set the timing manually without a scan tool... It won't be dead on exact, but the requirement field is between -2° to +2°... 0° being perfect but if anyone cares for an education, comment n I'll be happy ta teach a lesson it took me years to figure out n it's always within 1-2° of being dead on